Discover the Different Kinds of Screen Printing Techniques for Your Following Project

Screen printing offers a varied variety of methods that can boost any type of creative job. From typical techniques like serigraphy to modern-day developments such as direct-to-garment printing, each method has its special advantages. Specialty alternatives, including environmentally friendly and metal inks, introduce also extra possibilities. Recognizing these techniques can considerably affect the last outcome. The difficulty exists in selecting the most ideal technique for certain needs and preferred results. What elements should one consider?

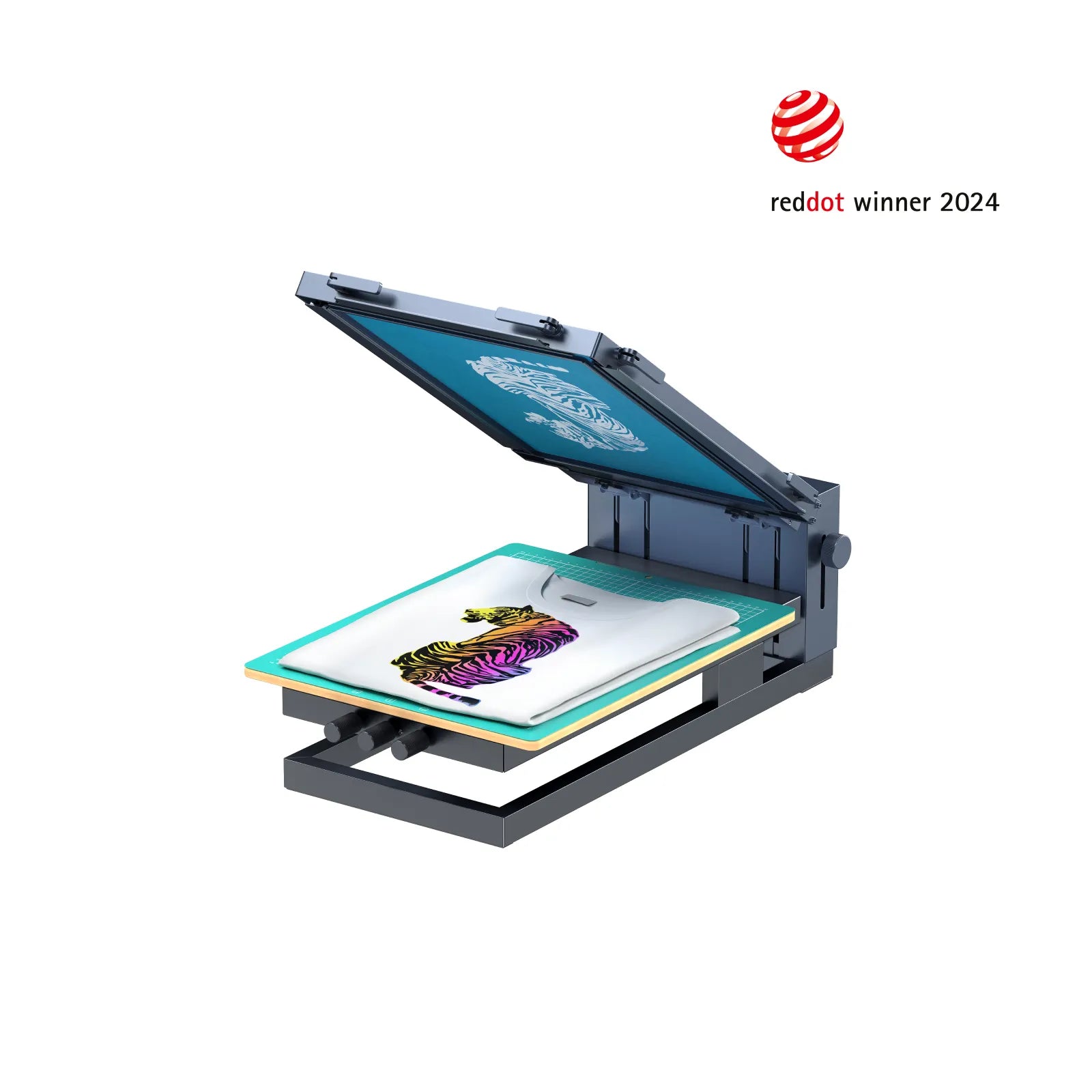

The Basics of Screen Printing

Screen printing may appear facility, it is basically a straightforward procedure that involves moving ink with a mesh screen onto numerous surfaces. The technique begins with the creation of a stencil, which specifies the style to be printed. This stencil is attached to a mesh screen, usually made from polyester or nylon. Once the pattern remains in location, ink is used to the screen and pushed with the mesh making use of a squeegee, leading to the preferred pattern being printed on the underlying material.

Screen printing can be executed on a vast array of substrates, consisting of textile, paper, and plastic, making it a versatile choice for various tasks. The process permits detailed designs and lively shades, making it popular in markets such as fashion, advertising and marketing, and art. Comprehending these essentials outfits individuals with the foundational knowledge required to check out even more advanced methods in screen printing.

Standard Screen Printing Techniques

Standard screen printing methods have actually been used for centuries, preserving the craftsmanship and creativity of this approach. This strategy uses a mesh screen to move ink onto a substratum, such as material or paper, permitting long-lasting and lively designs. The process begins with creating a stencil, which blocks particular locations of the screen to control where the ink will certainly be used.

One prominent technique is serigraphy, usually utilized for restricted editions and creative prints. One more is making use of water-based inks, which are environmentally friendly and give a soft feeling on fabrics - 10:9 Design Screen Printing. Furthermore, traditional techniques can consist of hand-operated printing, where artisans use ink with a squeegee, making certain accuracy and interest to information

These methods stay valued in the market for their responsive quality and the special textures they generate, appealing to both customers and developers who value the heritage of screen printing.

Digital Screen Printing Innovations

As the demand for faster manufacturing and personalization in the printing industry has surged, digital screen printing advancements have become a game-changer. This technology mixes standard screen printing techniques with electronic processes, permitting for quick prototyping and detailed designs that were previously tough to attain. One significant improvement is the introduction of direct-to-garment (DTG) printing, which facilitates premium, full-color prints on numerous textiles without the demand for screens. Furthermore, innovations in ink formulations have resulted in environmentally friendly alternatives that maintain vivid colors while lessening ecological influence. The usage of automated systems further streamlines production, reducing labor prices and improving accuracy. These innovations not just provide to little batch orders and customized designs yet additionally enable quicker turnaround times, making them excellent for companies concentrated on meeting consumer demands in a busy market. Digital screen printing, consequently, stands for an essential evolution in the domain name of printing strategies.

Specialized Screen Printing Techniques

Exploring specialized screen printing approaches exposes a varied range of techniques that press the limits of creativity and capability in the printing industry. Amongst these, glow-in-the-dark inks provide a distinct aesthetic impact, making designs come to life in low-light additional reading conditions. Metallic inks, recognized for their glittering surface, include a touch of deluxe to published materials. Another innovative method is discharge printing, which eliminates dye from the material instead of including ink, causing a soft, classic feeling. High-density printing produces a raised appearance externally, improving tactile involvement. Furthermore, water-based inks are acquiring appeal for their vibrant shades and lowered ecological effect. Each of these specialty methods accommodates details style needs, allowing musicians and brand names to create standout products that reverberate with their target markets. By leveraging these methods, businesses can raise their screen printing jobs to new elevations, ensuring remarkable impressions.

Eco-Friendly Screen Printing Options

Eco-friendly screen printing choices are acquiring traction original site as the market changes in the direction of sustainability. Lasting ink choices and using biodegradable materials are vital parts in lowering the environmental effect of the printing process. By embracing these practices, screen printers can add to an extra sustainable future while preserving high-grade results.

Sustainable Ink Choices

Biodegradable Materials Use

As the screen printing market develops, the consolidation of biodegradable products is becoming significantly vital for ecologically aware practices. Suppliers and developers are currently exploring inks and substrates made from natural, renewable resources that decay a lot more successfully than typical equivalents. These eco-friendly choices decrease plastic waste and decrease ecological influence, aligning with the growing need for lasting products.

Typical examples consist of water-based inks and natural cotton materials, both of which reduce dangerous chemicals and advertise eco-friendliness. Brand names that embrace these products often enhance their market charm, bring in customers that prioritize sustainability. As awareness of environmental problems proceeds to climb, the change in the direction of naturally degradable materials in screen printing is most likely to gain momentum, promoting a greener sector criterion.

Selecting the Right Strategy for Your Task

Exactly how can one figure out one of the most suitable screen printing strategy for a specific project? The decision depends upon a number of elements, consisting of the material to be published on, the complexity of the style, and the preferred production volume - 10:9 Design Texas. For my sources example, direct-to-garment printing is suitable for complex styles with numerous colors, while traditional screen printing excels for bigger runs of less complex graphics

In addition, factor to consider of the end-use of the published thing is necessary. For outside applications, methods that provide durability and climate resistance, such as plastisol ink, might be liked. On the other hand, environmentally-conscious projects might gain from water-based inks or eco-friendly materials.

Inevitably, comprehending the project's distinct demands permits for an educated selection, making sure both visual allure and practical long life. By evaluating design intricacy, product compatibility, and manufacturing range, one can properly select the most appropriate screen printing strategy to fulfill their task's goals.

Regularly Asked Inquiries

What Is the History of Screen Printing?

Screen printing came from in ancient China around 1000 AD, advancing via Japan and Europe. By the 20th century, it ended up being prominent in business art and fashion, reinventing exactly how designs were created and dispersed internationally.

Exactly how Do I Prepare Artwork for Screen Printing?

To prepare art work for screen printing, one need to assure high resolution, use an appropriate color mode, develop different layers for every shade, and convert message to lays out, guaranteeing compatibility with the printing process and preferred outcome.

What Products Are Best for Screen Printing?

The very best products for screen printing include high-quality inks, sturdy displays, and appropriate substratums like cotton, polyester, or blends. In addition, using proper solution and mops can enhance the printing procedure and last results.

Can I Evaluate Publish at Home?

Yes, screen printing in your home is possible. With the right products, configuration, and techniques, individuals can create top notch prints. Cautious consideration of workspace and tools is crucial for successful outcomes.

What Are Common Errors in Screen Printing?

Typical blunders in screen printing consist of inappropriate exposure times, inadequate ink uniformity, misalignment of displays, inadequate cleansing of products, and overlooking to test prints. These errors can endanger the top quality and precision of the last product.

Screen printing may seem complex, it is fundamentally a simple procedure that involves moving ink with a mesh screen onto numerous surface areas. As the need for faster manufacturing and modification in the printing industry has risen, electronic screen printing advancements have arised as a game-changer. Discovering specialized screen printing approaches discloses a diverse variety of strategies that press the borders of creative thinking and capability in the printing industry. The finest products for screen printing consist of high-grade inks, long lasting displays, and suitable substrates like cotton, polyester, or blends (10:9 Design Texas). Common errors in screen printing include inappropriate direct exposure times, insufficient ink consistency, imbalance of screens, inadequate cleansing of materials, and neglecting to examine prints